Impro is uniquely positioned to reliably meet high-volume demands quickly and efficiently. Our factory is home to the world’s largest glove dipping facility, with dedicated production lines for industrial work gloves and disposable nitrile gloves.

We also have direct access to manufacturing materials with our own in-house Rubber Formulation Center and a stand-alone production facility for our synthetic materials. This positions Impro with robust capabilities in both sourcing and manufacturing, allowing us to scale production on demand.

Best practices guide every production process at Impro. We maintain third-party certification in our systems for quality, environment, and social impact, following both domestic and international standards for worker protection, equipment maintenance, and product quality.

All factory operations are monitored by a central Distributed Control System (DCS), providing oversight at every link in the production chain. This end-to-end insight is what allows us to optimize for efficiency, driving down manufacturing costs for us and our clients.

Impro’s fully customizable hand protection range caters to all workplace and end-user requirements.

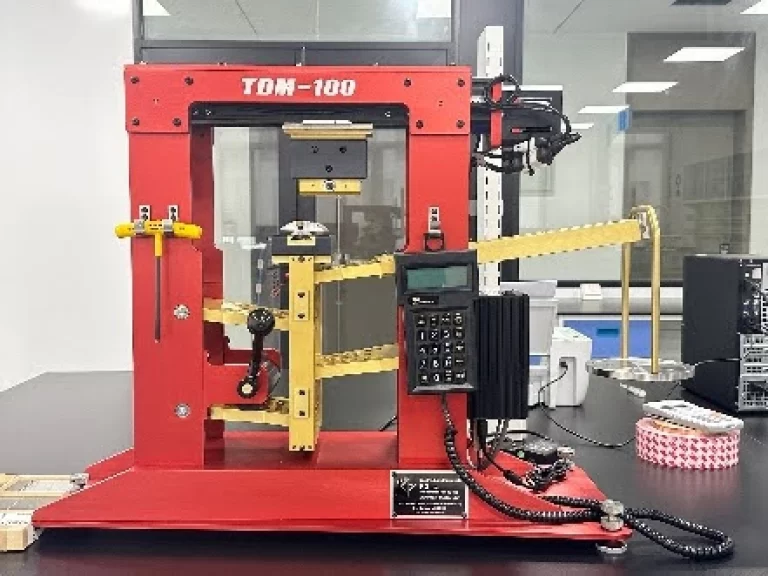

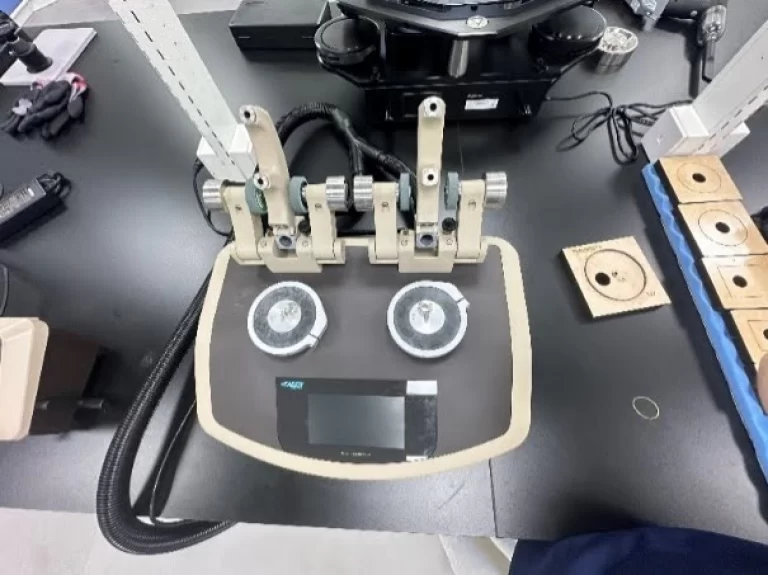

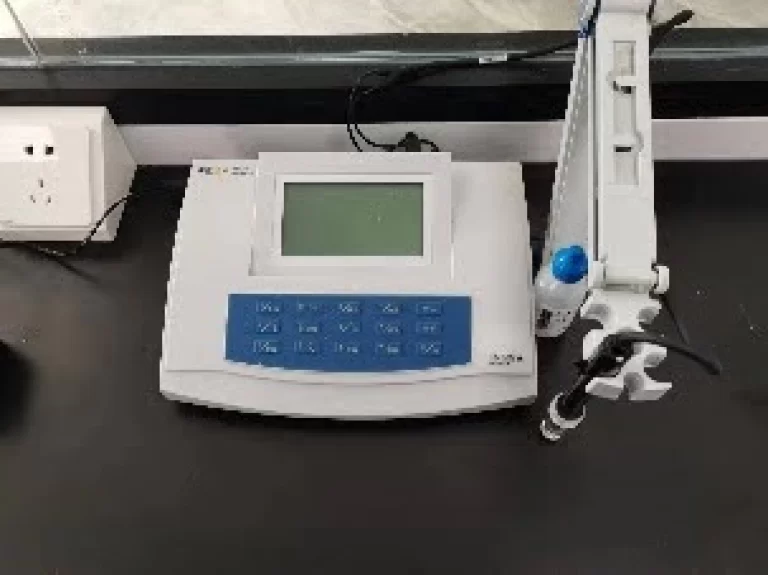

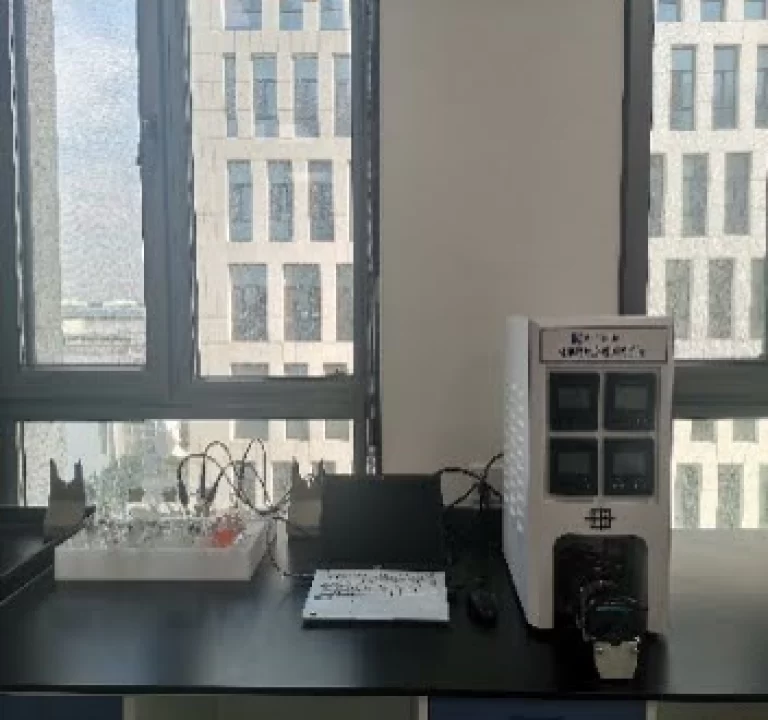

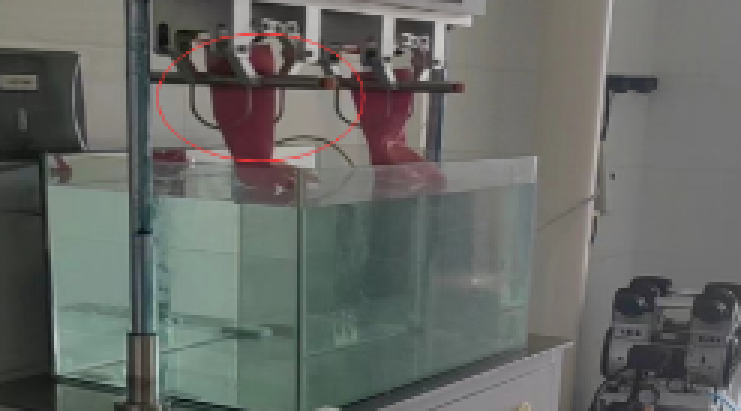

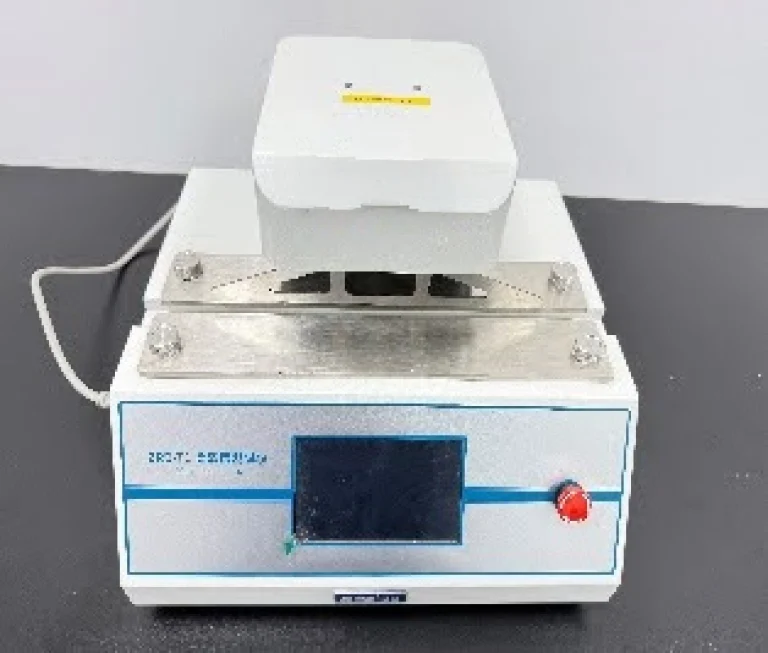

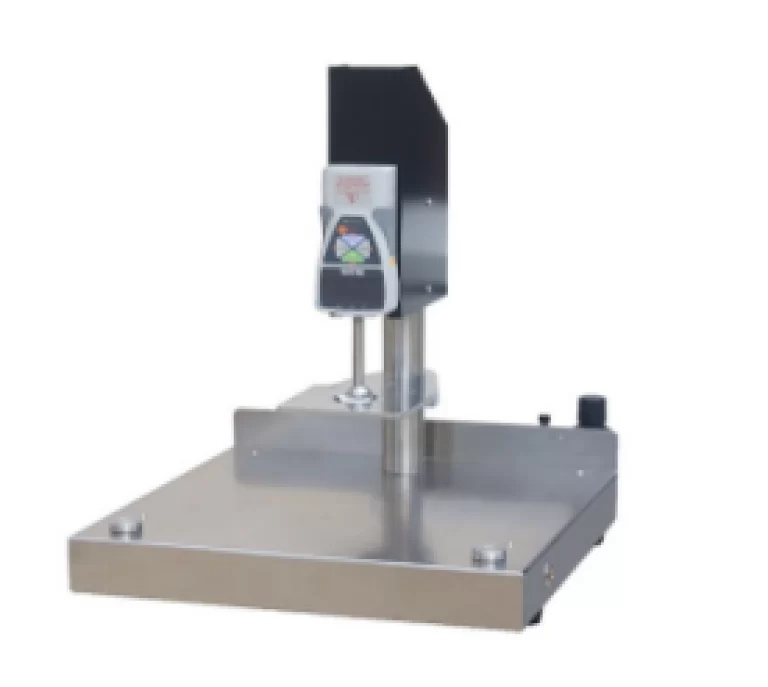

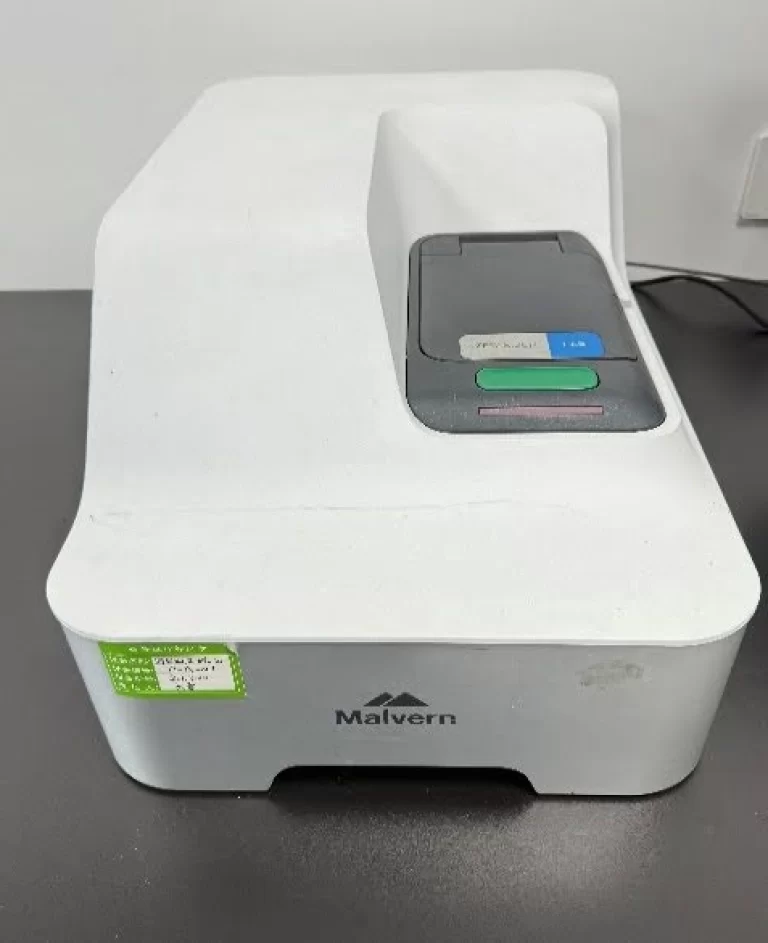

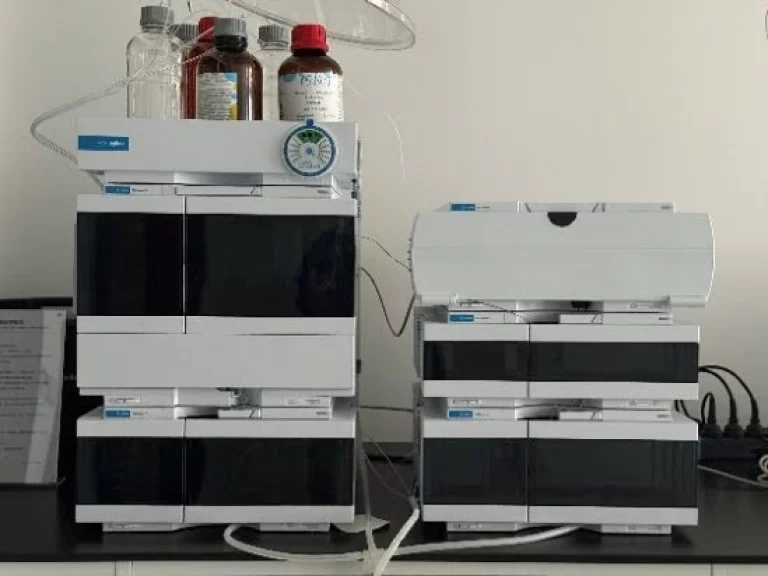

Run by qualified, experienced technicians, our lab is equipped with the latest analytical and performance testing equipment.